Main Technology and Equipment

We specialize in the rare

metals of the platinum group.

There are things

that only we can

accomplish.

With sophisticated technology developed through our engagement with iridium, ruthenium, and other metals that are difficult to work with and difficult to recover, Furuya Metal develops high-purity, high-quality products, and recovers platinum group metals (PGM) using our own exclusive technology.

Manufacturing Technology

-

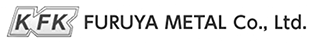

Plasma Melting and Sintering

Materials are melted in the high-temperature, high-pressure environment of a plasma melting furnace heated to a flame temperature of approximately 5,000℃. This leads to vaporization of impurities, enabling manufacture of high-purity, high-grade ingots. Using ultra-high temperature sintering technology, we are able to manufacture high-density, high-purity ingots even from material types not readily susceptible to melting and rolling.

-

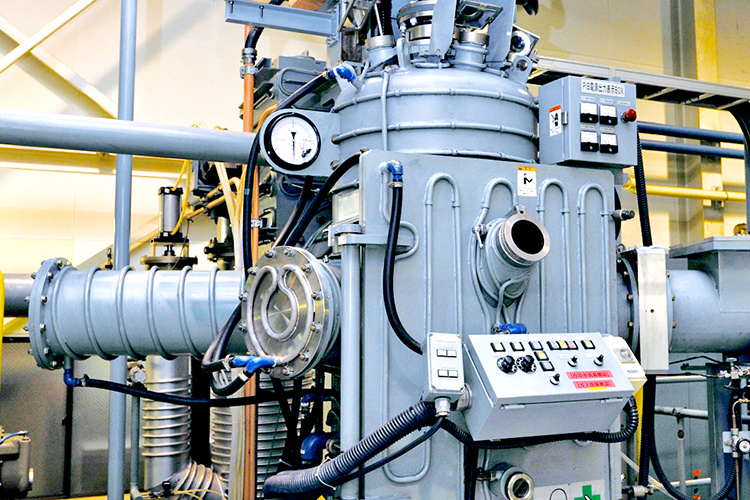

Rolling

Our premises are equipped with processing facilities such as plasma double melting machines, large-sized rolling mills, and cold/hot rolling mills that can respond to the trend toward large-dimension and high-precision specifications in PGM plate and which enable us to manufacture a diverse range of products. Our facilities are adapted for cold-rolling at up to 750 mmW and hot-rolling at up to 350 mmW.

-

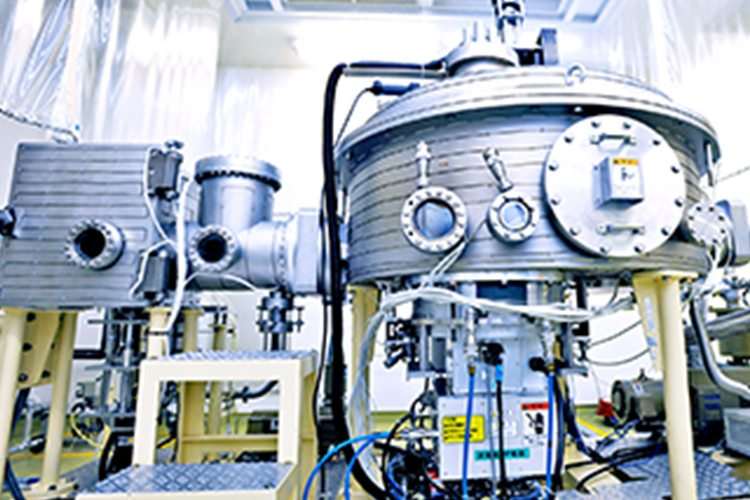

Thin-Film Technology

Our premises are equipped with Class 100 cleanroom facilities, enabling the manufacture of a wide range of sputtering deposition materials adapted to the customer development and manufacturing environment.

Processing Technology

-

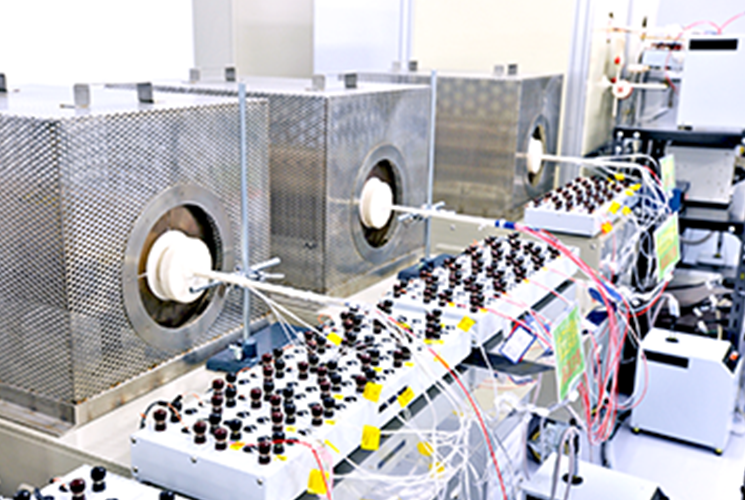

Thermocouple Assembly and Calibration

We carry out assembly processing in a Class 5000 cleanroom environment, while calibration is undertaken as an accredited enterprise compliant with the certification criteria of Article 143 of the Measurement Law and International Standard ISO/IEC17025.

-

Wire Discharge Devices

High-precision cutting of electric conductors allows us to manufacture a wide range of products, whether standard forms or irregular forms.

-

Instrument Manufacture

Our premises are equipped with expert processing technologies including welding and metal spinning facilities.

-

Analysis Technology

-

Raw Material and Product Analysis

We carry out a range of analyses from grade analysis of raw materials, products-in-process, and finished products using ICP-AES (inductively coupled plasma atomic emission spectroscopy) to morphological analysis of ultra-thin surface layers using SEM (scanning electron microscopy) and other techniques.

-

-

Recovery and

Refining Technology-

Recovery and Refining Technology

We possess original technology capable of recovering everything from high-grade through to low-grade materials. Speedy and high-precision recovery and high-purity refining are performed at special chemical plants.

-